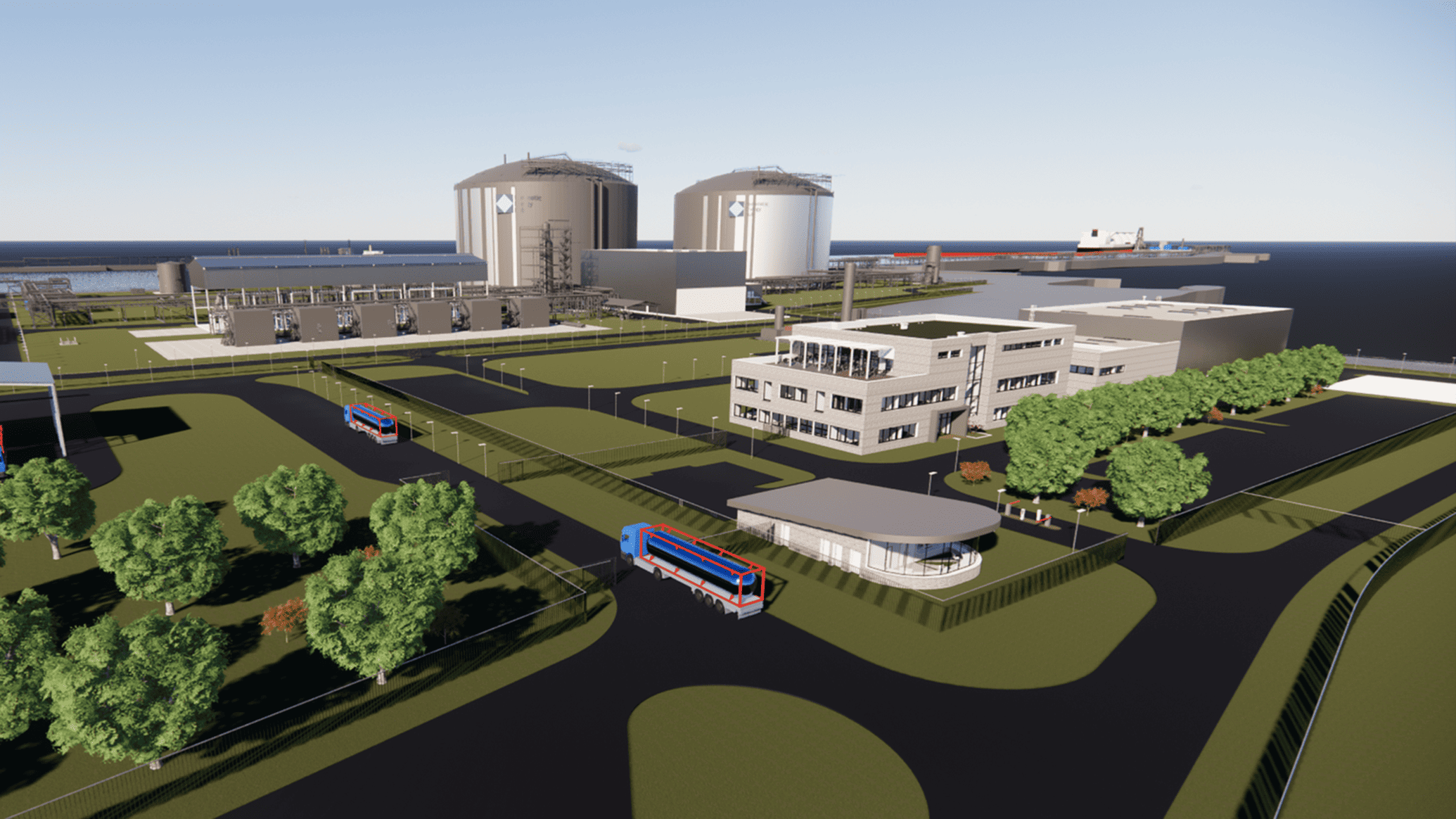

Stade LNG Terminal

Sofregaz Leading FEED Design in Germany

- Project Name: Stade LNG Terminal FEED

- Country : Germany

- Project Site Location : Stade

- Name of Client : Hanseatic Energy Hub (HEH)

- Project Type : FEED

- Completion Date : 2021

Located in Germany, the Stade LNG Terminal is designed to be a versatile facility capable of handling both small and large-scale LNG carriers. With two dedicated jetties, the terminal can accommodate ships of up to 265,000 m³, making it one of the most adaptable LNG facilities in the region. The project features:

- 2 x 240,000 m³ LNG storage tanks with full containment,

- Open Rack Vaporizers (ORV) utilizing warm industrial water for efficient vaporization,

- A backup heating system using fuel gas for winter operations.

This terminal is not only designed for unloading and reloading LNG but also supports ship-to-ship transfers and boasts a send-out capacity of up to 16 bcm/a, contributing significantly to Europe’s LNG infrastructure.

As the lead firm for the Front-End Engineering Design (FEED), Sofregaz plays a central role in ensuring the success of the Stade LNG Terminal. The FEED phase includes a detailed analysis and design of all critical systems, covering:

- Process engineering: Ensuring optimal LNG storage, vaporization, and send-out systems,

- Safety engineering: Implementing world-class safety measures, including emergency flare systems and hazard management,

- Piping design: Developing efficient layouts for LNG and vapor pipelines throughout the terminal,

- Mechanical and electrical engineering: Overseeing the mechanical components and power systems that keep the terminal running smoothly,

- Civil engineering: Coordinating the construction of the jetties, storage tanks, and supporting infrastructure.

LNG Storage and Vaporization

The 2 x 240,000 m³ LNG storage tanks use advanced containment technology to ensure the safe and efficient storage of LNG. The ORV system uses waste heat from nearby industrial facilities for LNG vaporization, reducing energy consumption and environmental impact. During the colder months, a backup heating system powered by fuel gas ensures continuous operations.

Dual Jetties and LNG Transfers

The terminal’s design includes two specialized jetties that allow for both small-scale and large-scale LNG carriers. With the capability for ship-to-ship transfers, the Stade LNG Terminal can handle multiple types of operations simultaneously, ensuring flexibility in handling LNG imports and exports.

Sustainability and Future Readiness

Sofregaz has integrated sustainability into the project’s design. By using industrial waste heat for LNG vaporization and incorporating state-of-the-art technology to minimize emissions, the terminal is positioned to meet stringent environmental standards. The facility is also designed to adapt to future energy transitions, potentially accommodating green hydrogen or other renewable energy sources.