eNG HUB – Phase 1 in Germany

FEED Design for e-NG Hub in Germany

- Project Name: eNG HUB - Phase 1 in Germany

- Country: Germany

- Project Site Location:Wilhelmshaven

- Name of Client: TES

- Project Type: FEED Design

- Completion Date: 2024

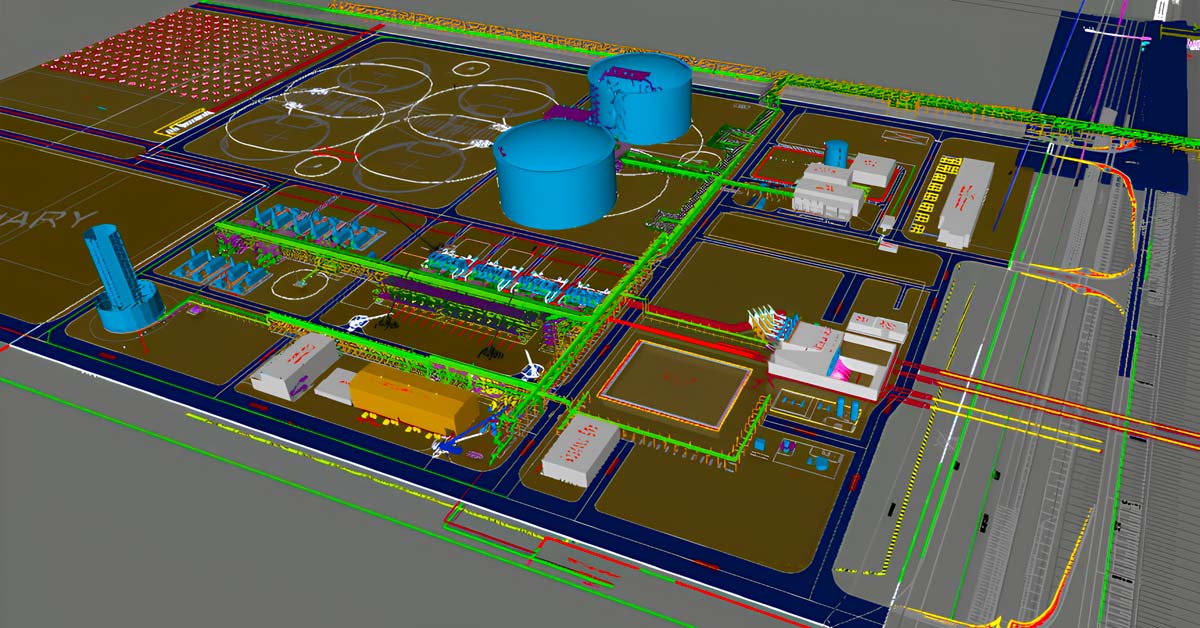

The eNG HUB Phase 1 in Wilhelmshaven, Germany, marks a critical milestone in Tree Energy Solutions (TES)' ambitious journey toward developing a green energy hub. With the focus on fostering a sustainable energy future, this project is designed to integrate innovative LNG storage and regasification facilities, supporting the import of liquefied natural gas for the European energy market. The project’s infrastructure includes:

- LNG storage tanks: Two large LNG storage tanks capable of holding significant volumes of gas.

- Regasification facilities: State-of-the-art regasification units that convert LNG back to natural gas for distribution.

- 2.4 km jetty: A robust jetty designed to accommodate LNG carriers of up to 266,000 m³ in capacity, ensuring flexibility in LNG import operations.

From July 2023 to March 2024, Sofregaz plays a pivotal role as the lead engineering firm for the Front-End Engineering Design (FEED) phase of the project. Our expertise ensures that the design of key systems — from LNG storage to gas export infrastructure — meets the highest standards of efficiency, safety, and sustainability. The FEED phase establishes the foundational engineering framework needed to move into the EPC (Engineering, Procurement, and Construction) phase seamlessly, with minimal risks and optimized costs.

LNG Storage and Regasification

The heart of the eNG HUB Phase 1 project is the 240,000 m³ LNG storage facility. These storage tanks are designed with advanced containment technology to ensure safe and reliable storage of LNG. Paired with high-efficiency regasification units, the facility converts the liquefied gas back into natural gas for distribution through the European network. Sofregaz’s engineering expertise in LNG systems ensures that these operations are executed efficiently while minimizing environmental impact.

Jetty Design and Ship-to-Shore Operations

The 2.4 km jetty allows the project to receive large LNG carriers, ranging in size from 30,000 m³ to 266,000 m³. With Sofregaz overseeing the design of the jetty and associated ship-to-shore LNG transfer systems, the terminal will be able to handle both small and large-scale LNG transfers, making it one of the most versatile terminals in Europe.

Sustainability and Environmental Considerations Sustainability is at the core of this project. The facility is engineered to support TES’s broader goal of reducing carbon emissions by using cleaner fuels like LNG. In addition to this, the infrastructure is designed to accommodate future green hydrogen integration, supporting the long-term transition to a zero-carbon economy. Sofregaz is committed to ensuring that the project complies with all environmental regulations and minimizes its carbon footprint throughout its lifecycle.